What happens when you’re 220 miles above Earth on the International Space Station, and you need a tool you don’t have? You can print one yourself.

In 2014, American astronauts, for the first time, printed a tool — a ratchet wrench — using a design file sent from NASA on the ground to the 3D printer spinning about in space.

The feat was straight of visions of Star Trek’s replicator — and it was only the first step to much larger miracles in space. Here’s what’s happening now and how 3D printing is changing everything about the future of space travel.

3D Printing Overcomes Zero Gravity

You may have heard that 3D printers can print food, but did you know that printing food in space overcomes a plating and serving problem, too?

“Unlike packaged food that floats in zero-gravity conditions, 3D printed food can be neatly formed and ordered,” said Anjan Contractor, CEO of BeeHex, who won a NASA grant for 3D printing pizza fit for deep-space missions.

While the astronauts still have to wear clunky anchor boots to stay in place, their pizza won’t.

The lack of gravity makes it hard to use a 3D printer in space. For one thing, you need the object you’re printing — whatever that object is — to stay together as it is printing and to stay aligned with the printer nozzle, or else you get printer mush.

That’s on top of the usual 3D printing problems. For example, if the object you’re printing is too far from the nozzle, it will collapse in the middle of printing. If it’s too close, the nozzle will clog as the object doesn’t have room to clear the end of the nozzle after each layer is printed. Sometimes — a lot of times — you can’t unjam the nozzle — ever.

Personal Butler and Chef

One of the most overlooked benefits of 3D printing in space is the ability to personalize products. Anything and everything an astronaut might need can be customized. Maybe the astronaut needs a bigger or smaller wrench than the one NASA printed. Done! Maybe the astronaut needs clothes that fit exact measurements or a special diet.

“3D printing provides dietary benefits as well,” BeeHex’s Contractor told TechNewsWorld. “3D printing fit for space missions typically includes a personalized nutrition regimen that can be tailored according to each passenger’s needs.”

Imagine all the things NASA doesn’t have to pack in a spaceship because they can be printed. What about printer ink or materials — will they have to be loaded on the ship? Not necessarily.

3D Printing in Space, of Space

“In the future, material mined from defunct satellites or even asteroids could be used for production in space,” said Tyler Benster, general partner at Asimov Ventures.

“When it comes to planets, the applications are even greater and more speculative. Habitats could be printed from a binder and the natural sand or terrain. Many common goods could be produced as necessary,” he told TechNewsWorld.

Sorry, FedEx and UPS, but it appears the sky is the limit for overnight deliveries. 3D printers can make do with the materials at hand.

“Right now, every manned launch has to have every conceivable tool and part the astronauts could need while in space,” said Liam Ginty of “Voices From L5” podcast.

“In the future, this could be reduced to bags of raw materials and only mission-critical supplies,” he told TechNewsWorld.

Recycling — and Creating — Waste

That means just about any material at hand. Already, 3D printers on Earth are producing homes out of construction waste or recycled materials.

Soon, 3D printers in space will be able to recycle things aboard a spacecraft that are no longer needed or waste from construction and other processes on an alien planet.

However, 3D printers themselves create waste.

The “main cons include dealing with waste and aerosol byproducts of common 3D printing methods,” Asimov Ventures’ Benster said.

The trimmings and general product cleanup also need to be dealt with. Yes, many 3D-printed products need a little trimming and polishing after printing.

“A lot of times, the printed parts will need some cleanup work before they can be used,” said Jeremy Irons, mechanical design engineer at Creative Engineering.

3D printer tech likely will improve over time, so there will be less waste, and whatever waste is produced can be recycled in some way.

NASA Can Pack Less — Sort Of

Until 3D printer tech improves, NASA has to work around its current limitations, and that means it still has to pack a lot of stuff in a spaceship.

“There are a lot of parts you can’t print. You can’t print a good bearing, and 3D printers have limited resolution,” Irons told TechNewsWorld. Limited resolutions nix most things with fine details.

Beyond packing stuff that can’t be printed easily, there’s also the need for multiple 3D printers.

“The materials that you can 3D print with are limited, and each material requires a different 3D printer,” Irons said. “A plastic printer can’t print metal, a metal printer can’t print composites, etc.”

Well, dang, and here I was planning on taking a bigger suitcase to bring alien mementos back home when they finally opened space travel to passengers. Then again, there may be room because some items will no longer be loaded preflight.

“3D printing will be a boon to space travel because it will allow astronauts to create items and spare parts on the fly, eliminating the need for stocking or emergency cargo flights,” said Tim Lynch, CEO at Psychsoftpc.

“It will also allow for more diverse experimentation since needed items can be created in flight rather than packed on the ground and brought along,” he told TechNewsWorld.

Emergency Units

Space travel is still dangerous. There will be unforeseen emergencies. Both real-life experience and science fiction movies have driven home that point.

“As amazing as NASA is, nothing in a space mission goes exactly as planned. Sometimes things break,” said Irons.

“Have you seen The Martian? This guy gets stranded on Mars for waaaayy longer than expected and things break. He needs additional tools he didn’t bring or left on the ship that left without him. If he had a 3D printer, he could have just printed most of the supplies he needed,” he added.

While The Martian may have been far less exciting if the main character had conjured everything he needed from a 3D printer, an astronaut in a real-life emergency doesn’t want to have to “science the hell out of this,” as the lead character said, to survive.

It’s one thing to be resourceful when you have air to breathe, but quite another to try to think clearly when you’re running out of oxygen because of your spacesuit or while you’re starving because NASA packed ready-to-eat meals and no actual potatoes for you to farm on Mars.

3D printers also could be used to produce human replacement parts like blood and organs. That’s very handy when you’re millions of miles away from the nearest blood bank or organ donor.

3D Printers Can Print Spaceships and Satellites

Printers can be lifesavers in space, but they also can take you to space.

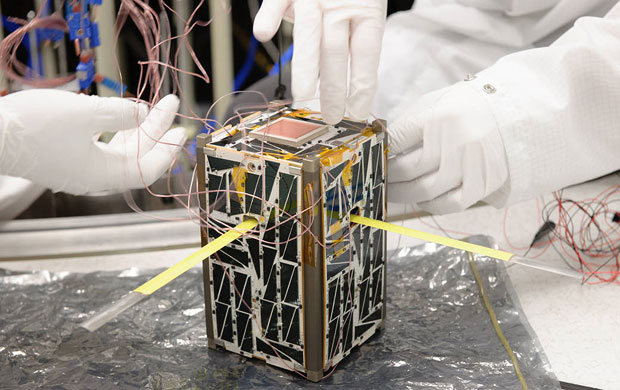

“3D printing is an enabling technology for space exploration as it can theoretically provide a tremendous reduction to costs,” said Asimov Ventures’ Benster. “Already, Made In Space and NASA are exploring using 3D printing to produce CubeSats.”

CubeSats are miniaturized satellites that can be used for lots of purposes. They could help astronauts call home or aid in setting up communications on a planet. They also can be used for a variety of exploration and experimentation needs.

That’s not all: 3D printers can be used to make spaceships, too.

“3D printing will eventually reach a point where it is the most economical way to manufacture any given item,” said Brent Hale, owner of Elite Gaming Computers and founder of 3D Forged.

“When that happens, the cost of building spaceships will dramatically decrease, thus allowing us to fly into space further and more frequently,” he told TechNewsWorld.

There you have it. From one NASA design file and a 3D-printed wrench on the International Space Station to the very backbone of space travel itself. Bet you’ll never look at a 3D printer in quite the same way again.

Raw material to 3D printer to product.

Product to waste to 3D printer to product. The perfect solution to a world running out of raw materials and drowning in waste. The future of production must include recycling and waste reduction. Great article.