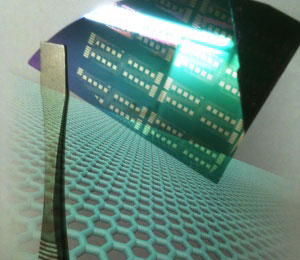

A developing technology using an ultra-thin layer of carbon atoms arranged in a honeycomb structure could start revolutionizing consumer electronics and many other industries in less than five years.

Known as “graphene,” the material’s special strength and conductivity make it an ideal component of super-fast, very sensitive and low-cost devices. Graphene is already being produced in enough quantities to support research and development projects; applications will include consumer products, security devices and health and safety applications.

“I do think there will be applications in the next couple of years that we will hear about,” Paul Smith, an engineer and patent attorney with the Graphene Practice Group of Fenwick & West, told TechNewsWorld.

“One of the endearing aspects of graphene is that it is not yet well-understood,” Smith noted. “It does not behave like other materials. People are sensing that new frontiers of technology are opening up.”

The technology has already progressed beyond the wishful-thinking stage, however, making Smith optimistic about seeing products in less than five years.

‘It Was Hard to Work With’

Scientists have been finding new forms of elemental carbon for a while, according to Smith. In 1985, for example, three British scientists discovered Fullerene.

That name was applied to two hollow carbon molecules. Those forming a closed cage were called “buckyballs.” Those forming a cylinder were called “nanotubes.”

Much excitement bounded to the scientific community over Fullerene, but the enthusiasm was short-lived. Fullerene never progressed into commercial product development, Smith pointed out.

“It was hard to work with,” he explained. “Nobody could figure out what to do with it product-wise to be commercially viable. There were lots of neat ideas in the lab that just could not get figured out.”

‘There Is a Lot of Excitement’

Two British scientists discovered graphene in 2004, and it was set apart early by indications that it was relatively easy to make, use and integrate.

The Royal Swedish Academy of Sciences in 2010 awarded the Nobel Prize in Physics to Andre Geim and Konstantin Novoselov of the University of Manchester, UK, based on their groundbreaking experiments with the material.

“There is a new excitement that has overcome the disappointments of earlier carbon projects based on Fullerene,” added Smith. “There is a lot of excitement because there is a lot of potential.”

Property Management

Graphene is a two-dimensional material consisting of zinc laced with carbon to form a single layer arranged in a honeycomb or chicken-wire structure. It is the thinnest yet strongest material known, said Mike Patterson, CEO of Graphene Frontiers.

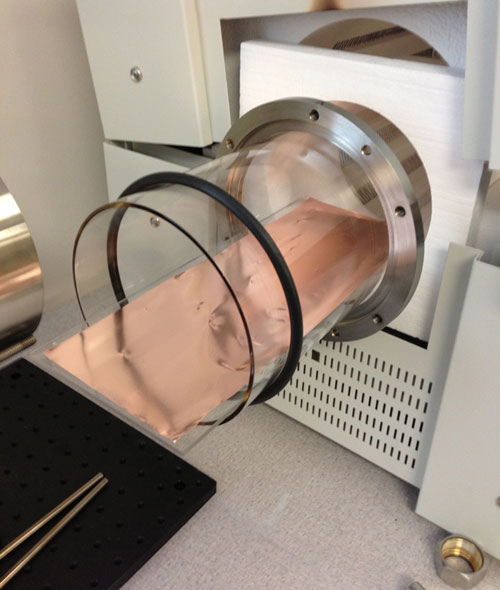

Patterson’s company has developed a process for making large-area pieces of this material. The National Science Foundation in early September awarded his startup tech firm a US$744,600 grant to develop roll-to-roll production of graphene.

Research and development expenses may mean that initial works with graphene technology are no less expensive than is developing products in other markets, like pharmaceuticals, but expectations are for much less costly production costs down the road due to the ease of mass-producing graphene seen so far, noted Patterson.

“Ultimately, it has the potential for becoming very cost effective,” Patterson told TechNewsWorld. “The big question is what is that first killer application, and how quickly can we ramp up production.”

One main reason for graphene’s potential is its durability and ability to conduct electrons and heat. It is 10 times stronger than diamonds and two times stronger than structural steel, Patterson pointed out.

Size Matters

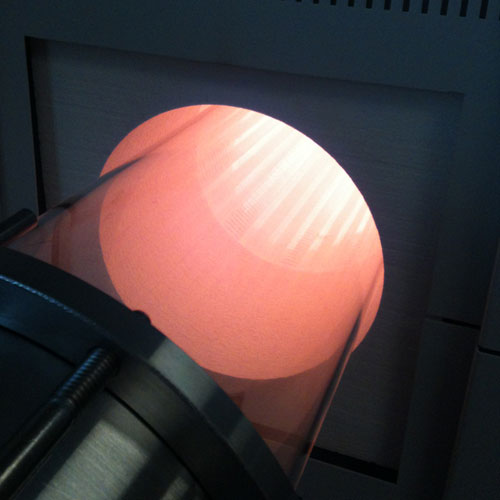

Making larger amounts of graphene cost-effectively is currently the overriding challenge. Toward that end, Graphene Frontiers has developed a process called Chemical Vapor Deposition to grow graphene films into larger quantities.

In 2010, making a single centimeter of graphene the size of a postage stamp cost tens of thousands of dollars. Currently, the company has scaled up to 300 square centimeters, or about the size of an iPad, Patterson said.

“Current efforts are to grow much larger quantities in single sheets,” he noted. “That will reduce manufacturing costs to produce sheets of graphene to pennies a square inch.”

Research Primer

Progress with graphene is already far beyond any expectations that formed around Fullerene, and researchers are making headway around the globe.

For example, Australian scientists have created the first graphene-based optical disc. That technology, in turn, is forming the basis for holographic storage with huge data capacity. Other researchers have created a silicon chip with an integrated graphene photo-detector.

Scientists at the Korean Advanced Institute of Science and Technology, meanwhile, created composite materials using graphene that are up to 500 times stronger than the raw, noncomposite material.

Range of Products

Graphene products will develop for several very big markets in years to come. In the near term, Patterson believes there are three main areas of application. One is food and water safety. There, graphene technology will enable faster detection of things like salmonella in processing plants before outbreaks occur.

A second application, point-of-care diagnostics, will take a bit more time to produce. University of Pennsylvania researchers have already demonstrated graphene’s ability to directly detect Borrelia, the culprit bacterium in Lyme disease. Other breakthroughs Patterson sees in the not-too-distant future with graphene technology include very sensitive detection of things like cancer biomarkers.

The third application area in the near term is chemical detection. This will provide new detection capabilities for military use and homeland security uses at ports of entry and airports, Patterson predicted.

According to graphene’s creators, new processes to create the substance are making it ready to start overtaking the use of silicon in electronic hardware. In fact, the British creators dubbed graphene sheets rolled into cylinders the future of computing. Graphene ribbons made from these nanotubes already function as graphene transistors.

An Uncertain Digital Future

That notion of graphene becoming a cheaper magic replacement for silicone may not be a universal view, however. Graphene may be more suitable for analog electronics than it is for digital electronics, according to Elias Towe, guest editor and leading graphene expert for the IEEE journal, Proceedings of the IEEE.

It will be difficult to justify graphene’s use as a silicone replacement in digital electronics, Towe contends, because graphene does not have a band gap. In solid-state physics, that property refers to an energy range in a solid where no electron states can exist, he explained.

That could limit graphene’s usefulness in some electronic circuits because it would conduct energy all the time — there is no way to turn it on and off, so it would consume too much power, according to Towe.

“At this stage up to now, no one has been able to show that you can make it work credibly in digital electronics,” Towe told TechNewsWorld. “In analog electronics, however, people are doing remarkable things with it.”

Still, if nothing comes along that is better than graphene, “we may be forced to find ways to make it work as a silicone replacement,” Towe said.

For example, a group of researchers at Stanford University have made a simple digital processor out of graphene, but not in the way one would want to make processors typically, he added.

“You can do this at a university, but you could not do this at a factory,” he said.

Pushing Products

Graphene is already being used in real products. For example, it is part of the materials used to reinforce some long-existing consumer items such as tires and tennis rackets.

It will take another five to 10 years before consumers will see more complex products made from graphene that they can actually use, Towe estimated. The products available now are more like test products, he suggested.

More complicated uses of graphene in electronic devices such as smartphones will take five years or more to develop, agreed graphene patent attorney and engineer Smith. Those are already complicated devices, so it is going to take considerable engineering, he said.

What to Expect

Initial graphene products will not be in electronics, according to Towe; more likely, early efforts will involve products made with graphene composites.

Such early products will involve inks, thermal barriers and thermal conductors — products that are easy to handle and do not involve precision manufacturing, explained Towe.

They’re also similar to what already exists in the market. People do not know about their use of graphene yet because the focus is on the properties of the products rather than graphene itself, he noted.

Other uses for graphene already in use in the energy arena are capacitors and electrodes as well as in solar cells where transparent electrodes permit light to go through instead of covering it up with metals. Traditional materials for these purposes are more expensive for manufacturers than graphene.

The Cost Factor

The issue right now is affordability. Graphene will not initially be any less expensive for consumers buying these first-generation graphene products as early adopters. Developers have a high investment in the material, according to Towe.

Most of the product development with graphene is occurring in Europe because the European Union has invested a lot more capital in its research than has the U.S. government. Just recently, for example, the European Union bet 1 billion euros on graphene development.

Research in the U.S., meanwhile, is on a bottom-up model. The government does not go out of its way to select what the researchers will be working on. Instead, it is based on what the researchers propose and what the government is willing to fund. Then manufacturers take over and make products out of it, Towe explained.

That does not mean that graphene-based products will first be released in Europe, however. People in the U.S. are very nimble in the sense of having an innovation culture, he pointed out, where little companies you’ve never heard about can do things overnight that giant corporations and governments can’t.

The Legal Connection

One indication of the feverish pace of graphene development currently is a noticeable uptick in patent applications, Smith noted.

“I am now seeing an unexpected boom in patent applications,” he said. “The role of [intellectual property] has changed since the earlier days with Fullerene in the 1990s. People are focusing on the IP and are worried that IPs can be used against them before they have even gotten products off the ground.”

One reason for this legal activity is that inventors want to protect their inventions. They do not want someone else to use their work unfairly, explained Smith.

The other factor graphene scientists are concerned about is that patents will be used by their competitors to block them early. Even if such claims are unjust, the efforts can be sunk early by expensive patent litigation. That’s the double-edged sword of patents, he added.

Looking Ahead

Those developing products have little doubt about graphene’s power and potential to reshape modern technology. Some of its main challenges are to bring the cost of production down and to ensure smooth integration with conventional silicon-based materials and technology, noted Jeanie Lau, professor of physics at the University of California, Riverside.

Imagine, for instance, mobile devices that can be rolled up or folded.

“Graphene could transform consumer electronics by enabling flexible electronics,” Lau told TechNewsWorld, “as it has the unique property of being a transparent, elastic and atomically thin membrane that also conducts electricity well.”